top of page

BSI Facilities

BSI Facilities

Two conveniently located BSI locations:

-

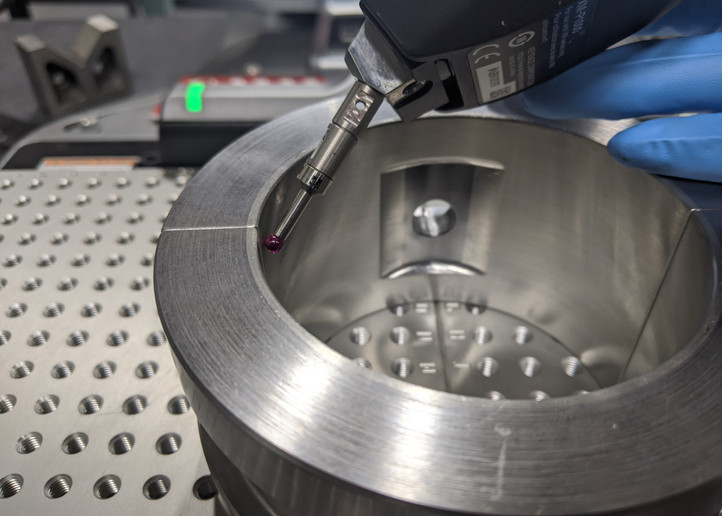

Corporate Headquarters - South Elgin, IL is a 45,000 sq Ft modern, climate controlled year round manufacturing facility located just outside Chicago. BSI incorporates brand new machinery and state-of-the-art CNC machining technology to provide the most accurate results.

-

BSI East ( Engineered Bearing Solutions ) Wellsville, NY is a 10,000 sq Ft Engineering office and manufacturing location. BSI East is staffed with talented engineers that can design, redesign, and modify existing designs for bearing efficiency and better performance.

Inspection

Babbitt Casting

bottom of page